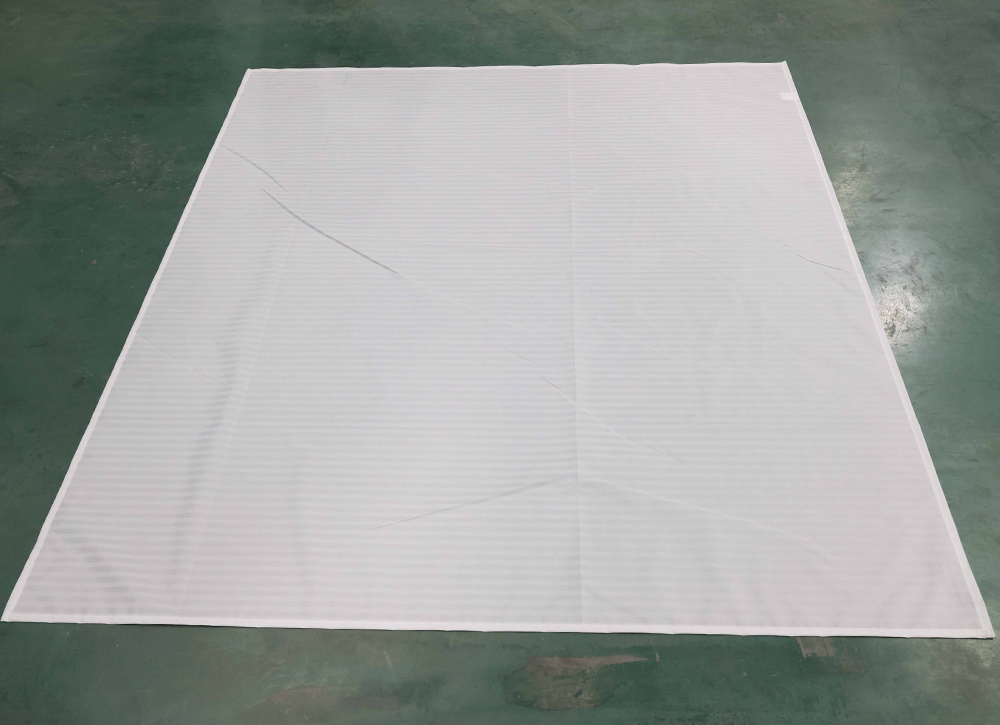

Automatic Bed Sheet Production Line

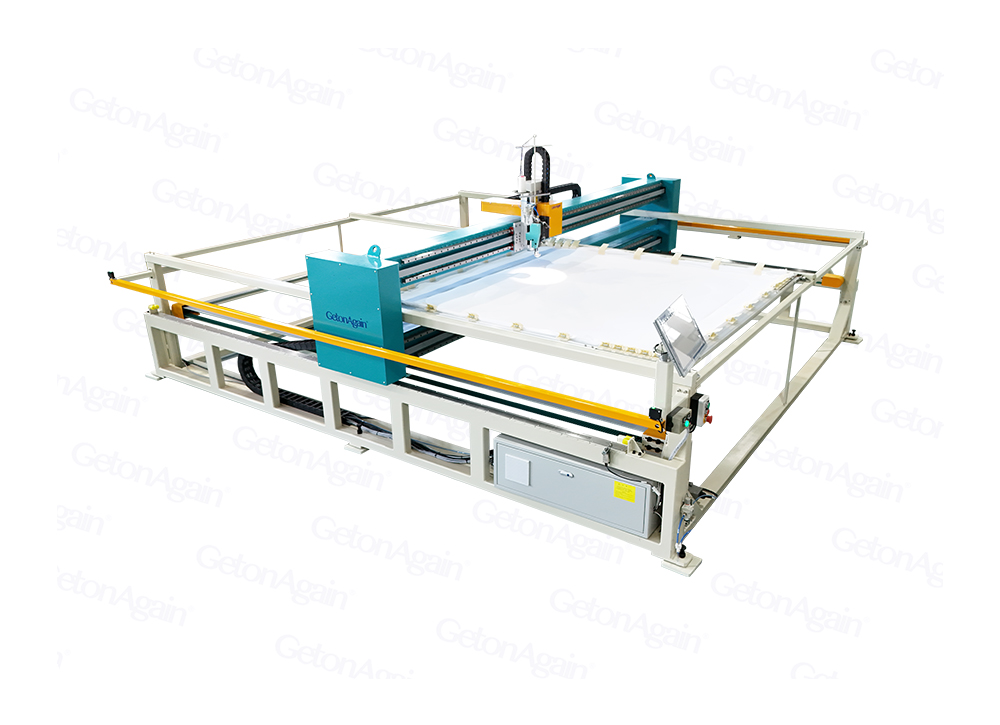

A fully automated bed sheet production line composed of a feeding mechanism, an adjustable-width longitudinal sewing mechanism, a fixed-length transverse cutting mechanism, an automatic transverse conveying mechanism, an automatic hemming transverse seam mechanism, and a discharging mechanism.

.png)

Equipment Advantages

1. Feeding Mechanism: Provides continuous raw material supply with functions like material shortage detection, independent material storage, fabric relaxing, and automatic alignment correction.

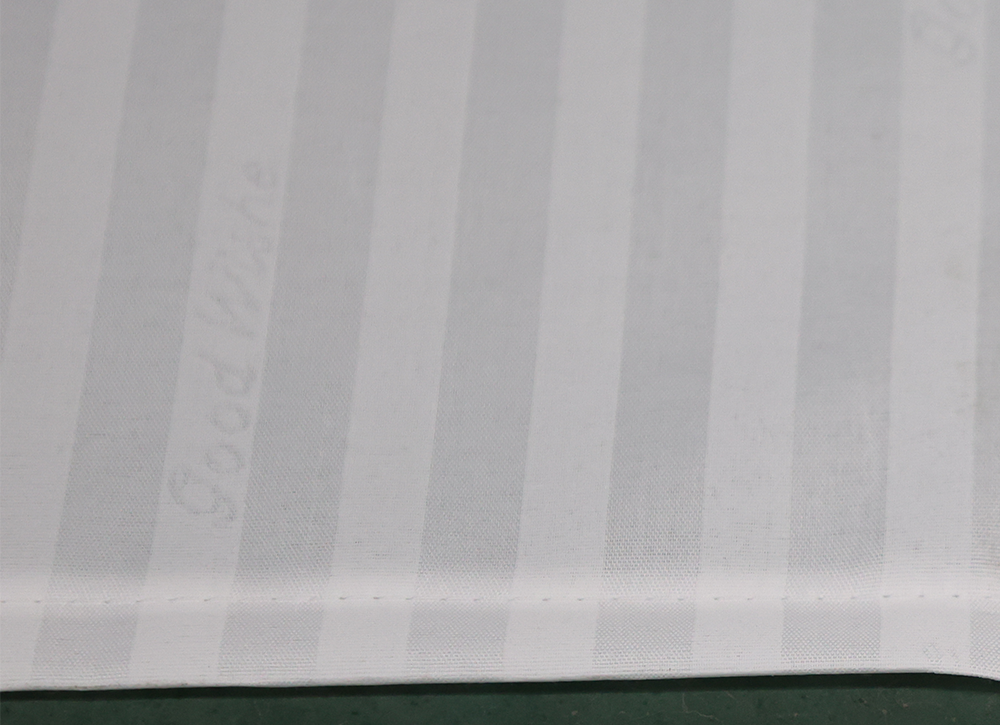

2. Longitudinal Sewing Mechanism: Steel structure with movable side seam sewing head, sewing width 1600-3000mm, equipped with thread breakage detection and automatic oil supply.

3. Transverse Cutting Mechanism: Automatically cuts longitudinally sewn fabric according to set length.

4. Transverse Sewing Mechanism: Upper pressure belt cooperates with loop-belt device for synchronized fabric transmission, sewing width 1500-2800mm, with edge trimming, waste collection, and automatic hemming functions.

5. Label Mechanism: Achieves automated label cutting and conveying, supporting folded and flat label structures.

6. Control Mechanism: Full servo control with GetonAgain control system and human-machine interaction, customizable based on customer needs.

| Model | Power (kw) | Machine Installation Size (L×W×H) |

|---|---|---|

| GOAAS-LM-ES-4-2800×3000-FS1-CN-AL,AT,AEG,ALF,CD-3P380 | 35kW | 16000mm×12000mm×3100mm |

Related Products

Mattress Border Multi-color Automatic Quilting Embroidery Cutting Machine

Computerized Single Needle Quilting Machine-lifting Head

Computerized Multi-needle Shuttle Quilting Machine (Flying Shuttle-Model N)

Computerized Multi-Needle Chainstitch Quilting Machine

Computerized Multi-head Rotary-hook Quilting Machine (Model E)

Automatic Ultrasonic Quilting Machine

Sales@raiseagaintech.com

Sales@raiseagaintech.com